In May 2020, I was bored.

Everything was shut down, closed borders prevented my mother-in-law from flying back to Europe so she was in the guest bedroom for three months, I got banned from the local subreddit for asking if there were any live music shows happening in the area, and Anya really wanted a Beetle.

So I bought one on Craigslist. It was undrivable and barely mobile, after sitting in a shop for several years. It was lacking a few important features, like a fuel tank, brakes, lights, seals, horn, you know, the basics.

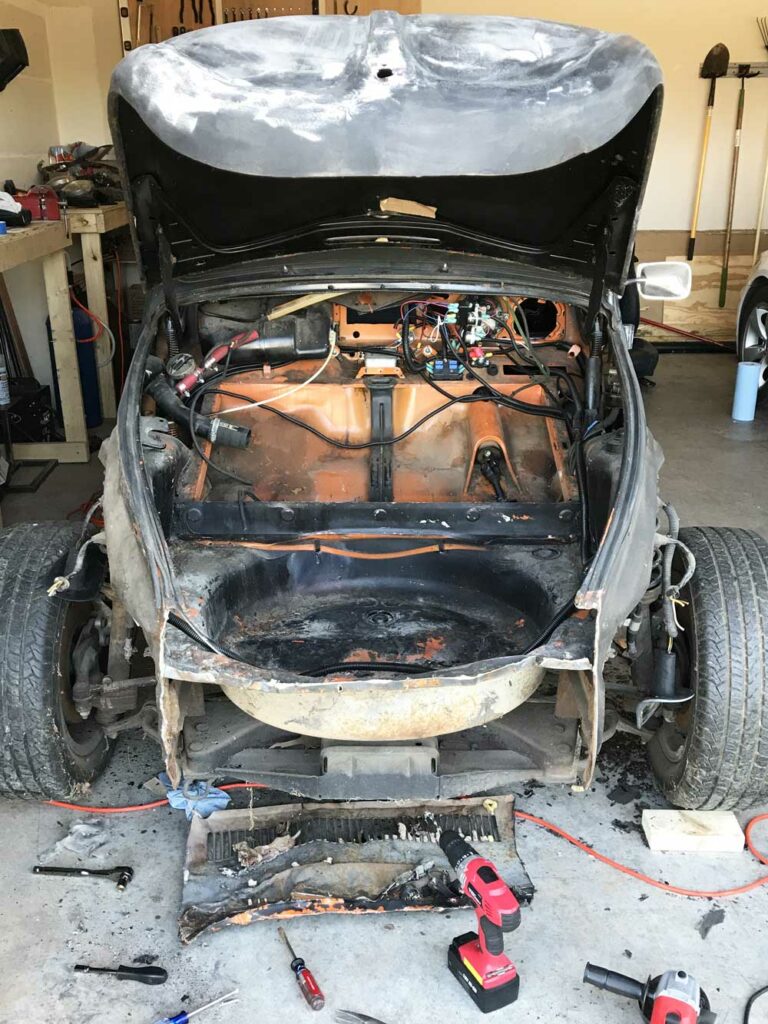

Here’s a few photos of the unrestored car.

Beautiful! I started hacking it up.

The first step was major body work. The car had obviously taken a hit to the front passenger side in the past, so there was a lot of welding and straightening to do.

I cut off the front bumper and apron assembly. I welded new panels in place and began a long process of painting the exposed body surfaces (both interior and exterior) in POR-15, which is a strong rust-preventative coating.

As I cleaned up the body panels, I started to wrap each one individually in 3M vinyl. Thinking about this retroactively, it was a pretty difficult process. In the future, I’ll likely just strip the next car down to bare bones and have a paint job done, but that would have been an expensive process for such a rough car. Vinyl wrapping is already difficult enough on flat panels, but every single surface of a Beetle is a learning curve (no pun intended).

Meanwhile, I’d been working on the engine.

The current engine ran (although not well). It was a VW block bored-out to 1776cc, but it had a weak single barrel Solex carburetor and was a leaky mess. Dropping the engine on a Beetle is a pretty easy process: it just takes a floor jack and a few bolts to drop it out the bottom.

I replaced valve springs, pushrods, pushrod tubes, manifolds, every gasket and seal, cooling tin, oil pump, fuel pump, heater hoses, and upgraded the carb to a dual Weber 34 ICT setup (which barely fit into the engine bay).

The engine was a long process. Taking a break every once in a while to work on the interior, I updated the seats, reupholstered the interior dashboard and carpet, and added a Blaupunkt radio, a push button start, a few new VDO gauges, steering wheel, horn, and wired up a standalone subwoofer controller for later.

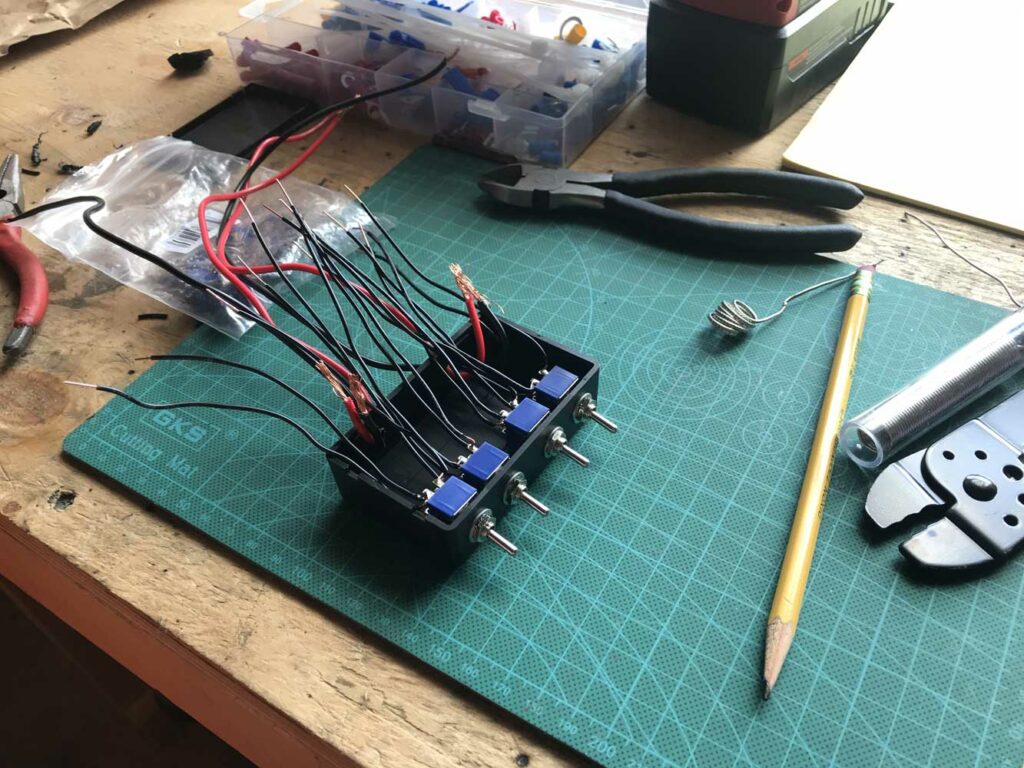

The current seats were terrible cloth seats pulled from a 1980s Golf. I removed them and sold them on Craigslist to a man from Oklahoma who bolted them into the bed of his pickup for his kids to ride in. I decided to upgrade to a pair of powered seats taken from a 2000 Porsche 911. This was actually one of the trickier elements of the whole car. While they fit in the Beetle physically with a little welding & bolting, it turns out that powered seats with memory modules require a computer to adjust. I had to build my own crude switch module to control the solenoids with standard 12v power.

Anya helped me dye the seats black.

Meanwhile I’d still been working on various mechanical elements. I replaced the shift rod coupling, every gasket in the entire car, ran new brake lines, replaced the axles and CV joints, added new Rally+ sport springs on the front, added lift springs in the back, fixed the steering box, replaced suspension bushings, replaced front struts, installed a new fuel tank, a new sending unit, welded up a new front bumper, added brush guards, rear bumpers, and a few more things I’ve either forgotten or chosen to forget.

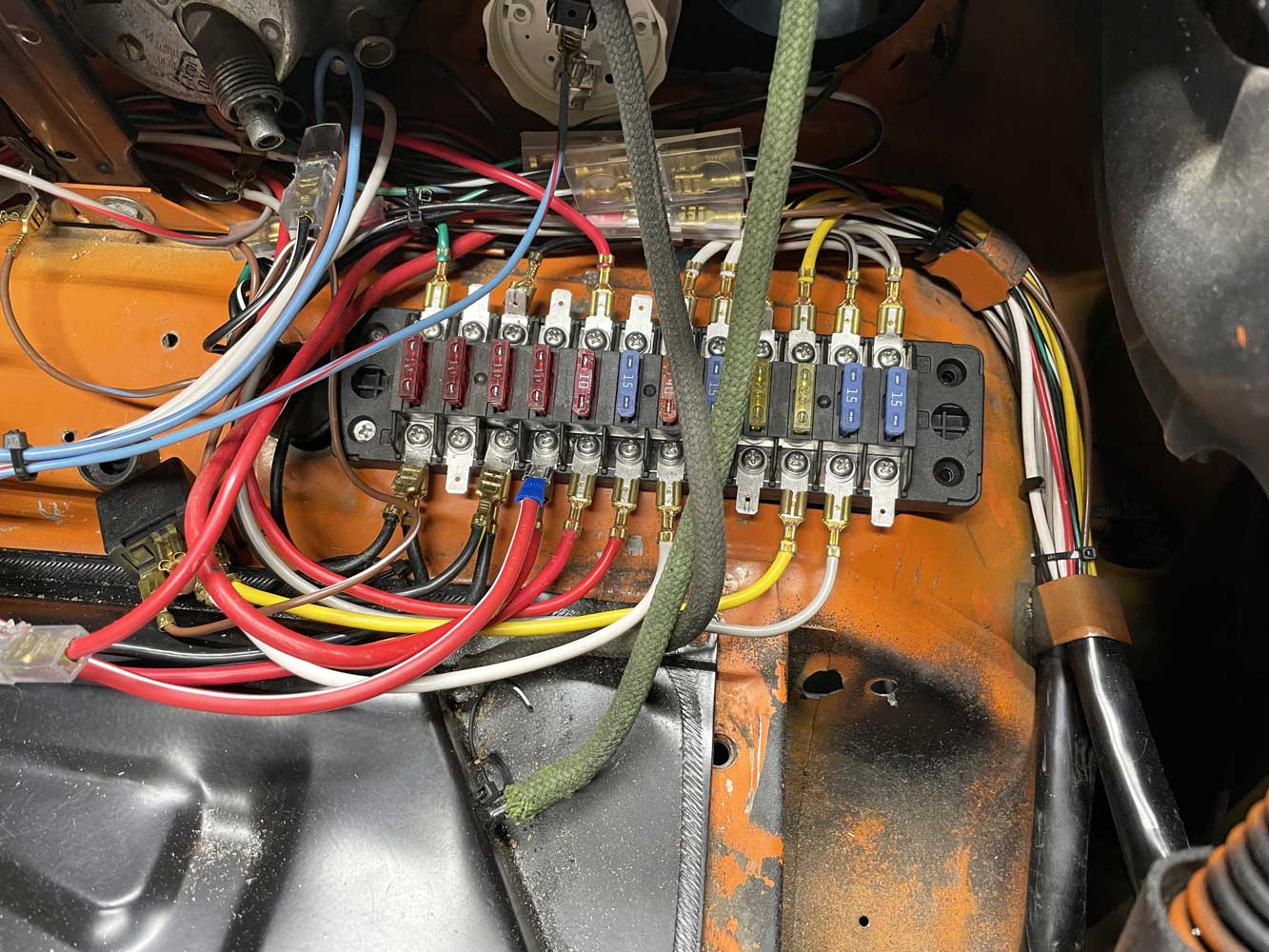

The worst part was the wiring.

After a few months of digging through this vehicle, I’d become absolutely disgusted with the existing wire loom, which had been spliced and cannibalized over the past 50 years until it was impossible to trace faults. I replaced the entire wire loom with a new one from Wolfsburg West. Although it was a huge project, it was worth it. Every single wire, relay, switch, voltage regulator, and electrical element was replaced. I upgraded the fusebox to a new blade-style setup and tried to route the wires more professionally:

Now that the power issues were fixed, I decided to put a strain on it. I built a ridiculous speaker shelf which included a massive subwoofer. Since I wanted to avoid too much strain on the power system, it had a cutoff switch on the dash and used a Class D marine amplifier with Bluetooth. To be honest, I never used it. The thing was too loud, and since the Beetle did not have a tachometer I couldn’t hear the engine in order to shift.

I sold the old wheels, and painted a new set of steel wheels along with some fat General Grabber AT/2 tires.

A little over a year in, and the car was finally drivable.

It ended up with the following specs:

- 1776cc engine

- Bosch 009 distributor

- Glasspack exhaust

- Dual Weber 134 ICT carbs

- Pertronix electronic ignition

- 15″ General Grabber AT/2 tires

- Top Line Rally+ Sport tapered lift springs

- 200w Blaupunkt stereo head/radio, amp + 5-speaker sub system

After lifting front & rear, the car ended up with almost 11″ of clearance. I took it in some serious mud, snow, ditches, and even tried a little off-roading from time to time.

Although no Beetle is truly fast, it was actually fairly peppy thanks to the 1776cc engine, dual carbs, and glass pack exhaust (it was also obnoxiously loud).

Seats were moderately comfortable.

Subwoofer/sound system was too loud.

The engine itself was beautiful, even though it barely fit in the engine bay after adding the carbs. I actually had to cut access panels in the fender wells in order to change spark plugs.

I crafted a cargo shelf to cover the spare tire in the frunk.

And now we come to the confusing part of the story: after a couple years of messing with the car, and not driving it as much as we thought, and not having enough garage spaces, we sold it.

This was the first car I’d gone through from the ground up. I learned a lot: mostly that it will take longer than you thought.

If i wanted to buy something exactly like this, how much do you think it would go for?

Before renovation? Probably able to get one with a solid body for $3-4k. After renovation? More like $10-12k.